A "platform" is not just adjacent pages in a catalog or on web-site

Product families must be based on all four of the

following criteria:

IMPLEMENTATION APPROACH

The forthcoming 2019 Second Edition of the author's DFM Book will show how building families of products on-demand can cut this much overhead costs:

Cut material overhead cost to1/10 for standard parts based on surveys of Procurement managers:

See opening page of Chapter 5: “Standardization” in the definitive book on Design for Manufacturability

Cut raw materials inventory down to /10 cost using:

Spontaneous Supply Chains,” Chapter 7, in the 512 page BTO book which starts with a 60 page Summary

Cut work-in-process (WIP) inventory Cost to 1/10 the usual cost , which can cost more than profits! See: “Design for Lean and Build-to-Order:” Chapter 4 in the author's DFM book, now translated into Chinese

Cut finished goods inventory Cost /10 of Mass Production cost by building all platform products to-Order "on-demand" without needing forecasted inventory. : See:

http://www.build-to-order-consulting.com/ or

"Build-to-Order & Mass Customization," the most thorough book written on Build-to-Order* See Overview of Inventory Reduction article at:

http://www.build-to-order-consulting.com/inventory_reduction.htm

With family products savings 10 times these overhead costs, those family products

could come close to making the case they not be charged any overhead charges at all!When the rest of the products can be build to-order in families,

then a total-cost based cost system will automatically assign all products proportionally less overhead cost.

A "platform" is not just adjacent pages in a catalog or on web-site

Product families must be based on all four of the

following criteria:

FLEXIBLE MANUAL ASSEMBLY

Note that when asked to deliver parts “on demand,” suppliers

will probably try to ship from their inventory

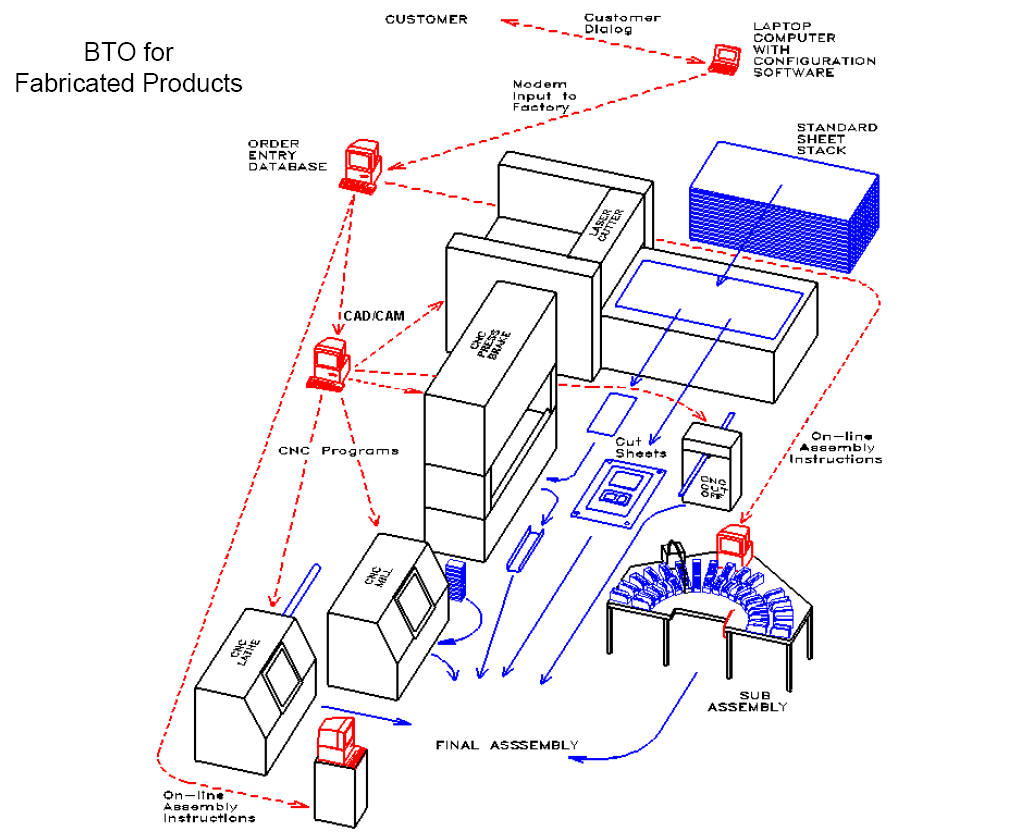

So if the existing production operations and supply chains can

not quickly

and cost-effectively build product families, the product families and their

processes

need to be concurrently engineered to make the product family strategy viable.

For more on BTO&MC principles see the book, Build-to-Order & Mass Customization

For an illustrated example of cellular manufacture for turned parts, go the bottom of the page at the Flexible Manufacturing page at http://www.build-to-order-consulting.com/flex-mfg.htm

Right-sized machine can

form complete mini-lines, in which no changeovers

are needed. The economics are

different with versatility and setup elimination

stressed over utilization.

Mass Customization

is the ability to quickly and efficiently build-to-order customized products.

It uses all the techniques presented so far

for the build-to-order of standard products and extends that to custom products.

These products can be customized for individual

customers or niche markets, such as versions optimized for certain market

segments, industries, regions, or countries.

For a secure enquiry form, go to the secure site: form (design4manufacturability.com)

These are the general principles. Pass around this article or URL to educate and stimulate interest

In customized seminars and webinars, these principles are presented in the context of your company amongst designers implementers, and managers, who can all discuss feasibility and, at least, explore possible implementation steps

In customized workshops, brainstorming sessions apply these methodologies to your most relevant products, operations, and supply chains.

Call or email about how these principles can apply to your company:

Dr. David M. Anderson, P.E., CMC

fellow, American Society of Mechanical Engineers

www.design4manufacturability.com

phone: 1-805-924-0100

fax: 1-805-924-0200

e-mail:

anderson@build-to-order-consulting.com

copyright © 2021 by David M. Anderson

Book-length web-site on Half Cost Products: www.HalfCostProducts.com

[DFM Consulting] [DFM Seminars] [DFM webinars] [DFM Books] [Credentials] [Clients] [Site Map]

[DFM article] [Half Cost Products site] [Standardization article] [Mass Customization article] [BTO article] [Rationalization article]